Hydropower industry

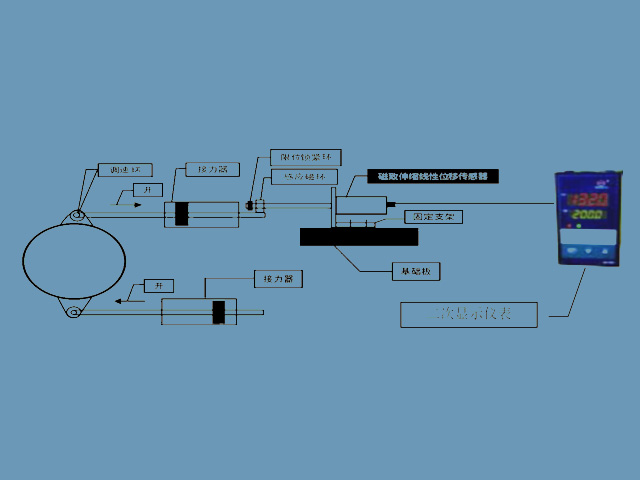

The auxiliary equipment control system of the hydropower station is divided into several small systems, each of which is composed of multiple control units. Among them, the control units such as the oil pressure device, governor device, oil leakage pump device, and lubricating oil pump device of the unit must perform real-time detection and monitoring of the oil level in the pressure oil tank, guide vane opening, oil leakage tank, and lubricating oil tank. The real-time oil level signal output by the sensor automatically opens and closes the air supply solenoid valve and starts and stops the oil pump, ensuring that the oil level is always within the normal working range. Therefore, in the on-site monitoring system of the local control layer, real-time collection of oil level parameters of the pressure oil tank, oil leakage tank, return oil tank, and three bearing lubricating oil tanks has become one of the key factors in power plant control. In the past, most hydropower stations used magnetic flip plates, reed switches, or single point magnetic induction switches with low accuracy to achieve automation. However, the control was chaotic, the faults were frequent, and the reliability was poor, which could not meet the automation requirements of modern hydropower stations with "unmanned and few personnel on duty". In this case, some hydropower stations have successfully replaced other products with magnetostrictive liquid level sensors. This product has won recognition from users for its stable output, accurate continuous measurement, fast frequency response, high reliability, long service life, and no need for regular maintenance, thus gaining a place in the automation control system of hydropower stations.